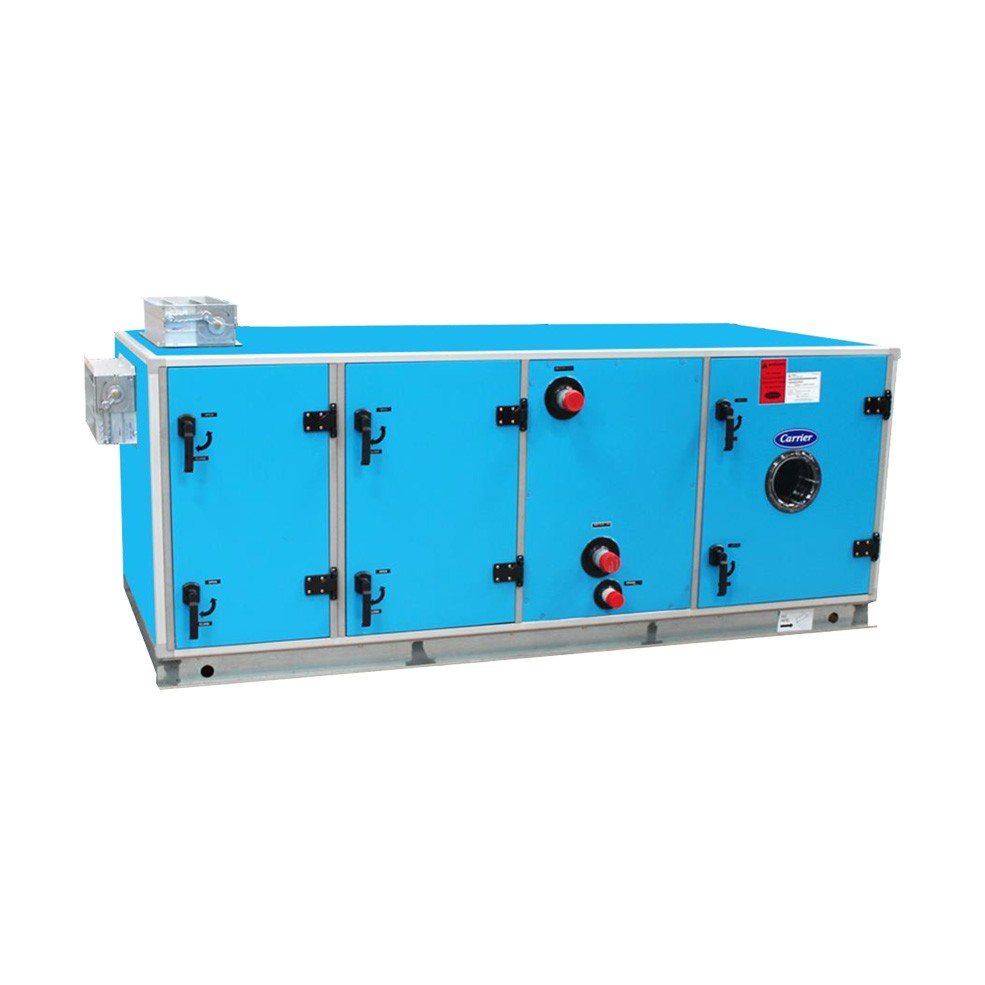

39CNE

Modular Air Handling Unit

39CNE [2,000~100,000 m3 /h] AIR HANDLING UNIT

The New, Versatile and Flexibility in Commercial Air Conditioning System

- Units are rated in accordance to AHRI Standard 430 whereas the coil performance shall be rated in accordance to AHRI Standard 410.

- Double-skin casing with 50mm(2”) 40kg/m3 CFC-Free PU insulation which isolates insulation exposure to the air stream.

- Chilled Water - 1, 2, 3, 4, 5, 6, 7, 8 rows with 8, 10, 12, 14 fin per inch.

- Hot Water - 1, 2, 3, 4, 5, 6, 7, 8 rows with 8, 10, 12, 14 fin per inch.

- DX Coil - 4 and 6 rows with 8, 10, 12, 14 fin per inch.

- All coils are factory pressure tested at 400 psig under water as standard with Nitrogen (N2 ) compressed dry air.

- Coil tracks enable easy coil removal for complete cleaning and assurance of a dry unit interior.

- Powder painted sloped galvanized steel drain pan with side drainage as standard (optional stainless steel drain pan).

- Optimized fan impeller size to meet performance criteria:

- Forward curved blade - sizes 160mm to 1000mm.

- Backward curved / Air foil blade - sizes 225mm to 1000mm.

- Plug fan - sizes 315mm to 1400mm

- Low leak construction with hexagonal socket compression, latch type and nitrile gasket on mating panel parameter

- Factory installed unit base of 100mm height, constructed of 10 gauge galvanized steel (optional 125mm height for marine application).

- Optional factory supplied Heat Recovery Wheel (HRW) or Horizontal Heatpipe for energy management application.

- Optional factory installed UVC lamp.

- Catalogue Carrier 39CNE Published Date: 26/01/2022

- Units are rated in accordance to AHRI Standard 430 whereas the coil performance shall be rated in accordance to AHRI Standard 410.

- Double-skin casing with 50mm(2”) 40kg/m3 CFC-Free PU insulation which isolates insulation exposure to the air stream.

- Chilled Water - 1, 2, 3, 4, 5, 6, 7, 8 rows with 8, 10, 12, 14 fin per inch.

- Hot Water - 1, 2, 3, 4, 5, 6, 7, 8 rows with 8, 10, 12, 14 fin per inch.

- DX Coil - 4 and 6 rows with 8, 10, 12, 14 fin per inch.

- All coils are factory pressure tested at 400 psig under water as standard with Nitrogen (N2 ) compressed dry air.

- Coil tracks enable easy coil removal for complete cleaning and assurance of a dry unit interior.

- Powder painted sloped galvanized steel drain pan with side drainage as standard (optional stainless steel drain pan).

- Optimized fan impeller size to meet performance criteria:

- Forward curved blade - sizes 160mm to 1000mm.

- Backward curved / Air foil blade - sizes 225mm to 1000mm.

- Plug fan - sizes 315mm to 1400mm

- Low leak construction with hexagonal socket compression, latch type and nitrile gasket on mating panel parameter

- Factory installed unit base of 100mm height, constructed of 10 gauge galvanized steel (optional 125mm height for marine application).

- Optional factory supplied Heat Recovery Wheel (HRW) or Horizontal Heatpipe for energy management application.

- Optional factory installed UVC lamp.

- Catalogue Carrier 39CNE Published Date: 26/01/2022

to find out more, you can contact us at

Inquiry Form Call Center: (+62) 21 2660 8088 Chat with us on Whatsapp