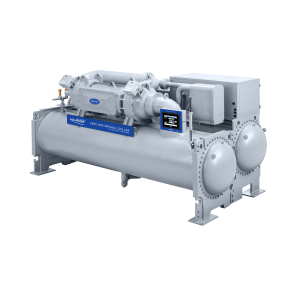

23XRV Water-Cooled Chillers

AquaEdge® High-Efficiency

Variable-Speed Screw Chiller

The 23XRV chiller is the world's first integrated variable-speed, water cooled, screw chiller. The 23XRV incorporates significant breakthroughs in water-cooled chiller technology to provide excellent reliability and achieve superior efficiency at true operating conditions without compromising the environment. Quality design and construction make the AquaEdge® 23XRV chillers the best choice for modern, efficient chilled water plants.

Carrier's AquaEdge® chillers offer the best value in high-efficiency chlorine-free variable-speed screw HVAC chillers.

Water-cooled chillers within the scope of the AHRI WCCL certification program are certified in accordance with the AHRI Water-Cooled Water-Chilling and Heat Pump Water-Heating Packages Certification Program, which is based on AHRI Standard 550/590 (I-P) and AHRI Standard 551/591 (SI). Certified units may be found in the AHRI Directory at www.ahridirectory.org.

Performance Features

- IPLV to 0.299

- Chlorine-free HFC-134a refrigerant

- Full Load kW/Ton to 0.53

- Tri-rotor, positive displacement screw compressor

- Hermetic compressor motor

- Refrigerant-cooled, unit-mounted variable frequency drive

- Low inrush current

- Operation of up to 0.99 power factor

- Flooded shell-and-tube cooler

- Float valve

- Superior oil management/cold condenser water operation

- Internally and externally enhanced 0.025 in. (0.635 mm) copper tubing

- 150 psig (1034 kPa) rated cooler and condenser

- LCD control display

- Microprocessor-based Product Integrated Control (PIC) III

- Multilingual display

- Demand limiting capability with Carrier Comfort Network® (CCN) communication link

Reliability Features

- ASME constructed heat exchangers

- PED/CE construction option

- Low voltage control circuits

- Lowest industry refrigerant leakage rate at less than 0.1%

- Hermetically sealed compressor motor

- Automated controls may be tested before start-up

- 65K AIC circuit breaker

Maintenance Features

- Password protected extensive service menu with built-in diagnostic capabilities, troubleshooting, and corrective action recommendations for preset alarms

- Alarm and alert files maintain the last 25 time and date stamped messages in memory

- Configuration data backup with non-volatile memory

- Refrigerant filter isolation valves

- Thermistor type temperature sensor with quick connects in each water nozzle

- Service contract available

Factory-Installed Options

- Enhanced tubing, .028 or .035 in. (0.711 or 0.889 mm):

- Internally/externally enhanced copper tubing - cooler/condenser

- Internally/externally enhanced cupronickel tubing - condenser

- Smooth bore/externally enhanced copper tubing - cooler/condenser

- Smooth bore/externally enhanced cupronickel tubing - condenser - Wall tubes, titanium, condenser, .025 or .028 in. (0.635 or 0.711 mm):

- Internally enhanced tubes

- Smooth bore tubes - Marine waterboxes (available for heat exchanger frames 3-5 only):

- 150 psig (1034 kPa) waterbox

- 300 psig (2068 kPa) waterbox - Nozzle-in-head waterbox, 300 psig (2068 kPa)

- Hinged waterboxes

- Flanged cooler and/or condenser waterbox nozzles

- One, 2, or 3 pass cooler or condenser waterside construction

- Zinc anodes

- 100K AIC high interrupt circuit breaker with shunt trip

- Analog voltmeter and ammeter with 3-phase selector switch

- DataLINK™ or DataPort™ communication device

- Shipped factory charged with refrigerant

- Hot gas bypass

- Full cold surface thermal insulation (except waterbox covers)

- Customer factory performance testing

- Export crating

Field-Installed Accessories

- BACnet™ Carrier translator

- DataLINK™ or DataPort™ communication device

- LonWorks® Carrier translator

- Sensor package

- Separate storage tank and pumpout unit

- Stand-alone pumpout unit

- Soleplate package

- Spring isolator kit

- Refrigerant isolation valves for in-chiller refrigerant storage

- Unit-mounted pumpout unit for storing refrigerant inside the chiller during servicing

- Acoustical sound insulation kit

- Shipped fully charged

| Nominal Capacity (Tons)* | Heat Exchanger Size | Length with Nozzle-in-Head Waterbox | Width | Height | |||||

|---|---|---|---|---|---|---|---|---|---|

| 2-Pass** | 1 or 3-Pass | ||||||||

| ft-in | mm | ft-in | mm | ft-in | mm | ft-in | mm | ||

| 250-550 | 30 to 32 | 13-8¼ | 4172 | 14-3¼ | 4350 | See Unit

Certified Drawings |

See Unit

Certified Drawings |

||

| 35 to 37 | 15-4¾ | 4693 | 15-11¾ | 4870 | |||||

| 40 to 42, 4D

|

14-3 1⁄8 | 4347 | 14-9 | 4496 | |||||

| 45 to 47, 4E

|

15-11 5⁄8 | 4867 | 16-5½ | 5017 | |||||

| 50 to 52 | 14-4½ | 4382 | 14-10 | 4521 | |||||

| 55 to 57 | 16-1 | 4902 | 16-6½ | 5042 | |||||

*For job specific dimensions and weight information, please contact your Carrier Sales Representative.

**Assumes all customer connections are on the same end of the chiller.

- Catalog Carrier 23XRV Published Date: 30/05/2023

- 23XRV Guide Specifications, 175 to 550 Tons (615 to 1934 kW) Nominal_Published Date 3.1.2018 Published Date: 01/03/2018

- 23XRV AquaEdge® High-Efficiency Variable Speed Screw Chiller with with Greenspeed® Intelligence, 50-60 Hz, HFC-134a Published Date: 14/08/2020

- Carrier® ChillerVu™ 23XRV Series Counterflow Application Guide Published Date: 05/04/2021

- Carrier® ChillerVu™ Variable Flow Condenser Pump Application Guide Published Date: 21/12/2020

- EverVu™ Touch Screen Display for Evergreen® 19XR,XRV, 23XRV Chillers with PIC II or PIC III Controls Published Date: 11/07/2015

- Carrier Evergreen 23XRV Water-Cooled Chiller Provides Full-Load and Off-Peak Energy Savings_Published Date 7.10.2015 Published Date: 10/07/2015

- Carrier Introduces New Evergreen Variable Speed Water-Cooled Screw Chiller Published Date: 10/07/2015

- Carrier Moves the Frontier on Efficiency Published Date: 10/07/2015

- Press Release - Carrier AdvanTE3C Optimized Central Plant Solution Reduces Cooling Energy Consumption up to 50 Percent Published Date: 10/07/2015

- Press Release - Carrier AquaEdge® 19XR, 23XR and AquaForce® 30XV and XA Chillers are Available With Lower Global Warming Refrigerant Solutions Published Date: 09/02/2018

- Press Release - Carrier Leads the Industry with the Most Complete Line of Seismic-Compliant Chillers Published Date: 10/07/2015

- Press Release - Carrier Offers Capacity RECOVERY Protection for Mission Critical Market_Published Date 7.10.2015 Published Date: 10/07/2015

- Press Release - Carrier Releases Updated Chiller Mobile App Published Date: 08/08/2019

- Press Release - Carrier Stocks Commercial Applied Products for Rapid Delivery Published Date: 10/07/2015

- Press Release - Carrier to Display Wide Range of Intelligent, Sustainable Building Solutions at AHR Expo Published Date: 16/07/2015

- Press Release - Carrier® Evergreen® 23XRV with Foxfire® Compression Technology Surpasses Industry Efficiency Standard by Up to 44 Percent Published Date: 10/07/2015

- Press Release - Carrier® Expands AquaEdge™ 23XRV Line Published Date: 10/07/2015

- Press Release - Carrier® SMART Service Delivers Enhanced Chiller Performance Published Date: 14/02/2017

- Press Release - Seismic Compliant WeatherMaker (PDF) Published Date: 10/07/2015

- Press Release - U.S. Government Study Finds Variable-Speed Screw Chiller Technology More Efficient Published Date: 15/02/2018

- Press Release -Carrier® to Display Extensive Range of Commercial Products at 2014 AHR Expo in New York Published Date: 10/07/2015

- California Hotel & Casino Published Date: 10/07/2015

- Cashman Center Finds Comfort and Savings with Evergreen® 23XRV Chillers Published Date: 10/07/2015

- Center for Intelligent Buildings Published Date: 10/07/2020

- Crowne Plaza Published Date: 10/07/2015

- Gaston County Medical Building Published Date: 10/07/2015

- Iron Mountain Published Date: 25/10/2018

- LCO Building Published Date: 10/07/2015

- Lehigh Valley Health Network Published Date: 30/11/2016

- Mangabeira Shopping, Brazil Published Date: 07/08/2017

- Mater Hospital, Queensland Published Date: 10/07/2015

- Nemours Children's Clinic Published Date: 10/07/2015

- Shore Medical Center Published Date: 10/07/2015

- University of Maryland Shock Trauma Tower Published Date: 15/05/2017

- Washington Navy Yard Published Date: 16/07/2015

- Waterville TG Published Date: 10/07/2015

- 23XRV AquaEdge® High-Efficiency Variable Speed Screw Chiller with Greenspeed® Intelligence, 50-60 Hz, HFC-134a, 175 to 550 Nominal Tons (615 to 1934 Nominal kW) Published Date: 06/02/2020

- Carrier® ChillerVu™ Chilled Water System Optimizer Product Data Sheet Published Date: 24/03/2021

- Carrier® ChillerVu™ PSM-IO Product Data Sheet Published Date: 17/12/2020

- i-Vu Open UPC Open Factory Installed Product Data Sheet Published Date: 17/12/2020

- Better Than Oil-Free, Why Screw Chillers with Pure Speed Capacity Control Save More Energy Than Magnetic Bearing Chillers Published Date: 16/07/2015

- Chilled Water System Optimizer Published Date: 11/04/2019

- Mechanical Room Update, Considerations In The Application Of Centrifugal Chillers Using Open Drive Motors Published Date: 10/07/2015

- Variable Frequency Drive, Operation and Application of Variable Frequency Drive (VFD) Technology Published Date: 30/07/2018

- Variable Speed Screw Compressor, Raising the Bar for Variable Speed Performance Published Date: 10/07/2015

- 19XRV, 23XRV Chillers with PIC III-PIC 6 Controls, Eaton LCX9000 VFD Option Published Date: 26/08/2019

- 19XRV,23XRV Hermetic Centrifugal Liquid Chillers with PIC III-PIC 6 Controls, Rockwell PowerFlex 755 VFD Option Published Date: 28/08/2019

Performance Features

- IPLV to 0.299

- Chlorine-free HFC-134a refrigerant

- Full Load kW/Ton to 0.53

- Tri-rotor, positive displacement screw compressor

- Hermetic compressor motor

- Refrigerant-cooled, unit-mounted variable frequency drive

- Low inrush current

- Operation of up to 0.99 power factor

- Flooded shell-and-tube cooler

- Float valve

- Superior oil management/cold condenser water operation

- Internally and externally enhanced 0.025 in. (0.635 mm) copper tubing

- 150 psig (1034 kPa) rated cooler and condenser

- LCD control display

- Microprocessor-based Product Integrated Control (PIC) III

- Multilingual display

- Demand limiting capability with Carrier Comfort Network® (CCN) communication link

Reliability Features

- ASME constructed heat exchangers

- PED/CE construction option

- Low voltage control circuits

- Lowest industry refrigerant leakage rate at less than 0.1%

- Hermetically sealed compressor motor

- Automated controls may be tested before start-up

- 65K AIC circuit breaker

Maintenance Features

- Password protected extensive service menu with built-in diagnostic capabilities, troubleshooting, and corrective action recommendations for preset alarms

- Alarm and alert files maintain the last 25 time and date stamped messages in memory

- Configuration data backup with non-volatile memory

- Refrigerant filter isolation valves

- Thermistor type temperature sensor with quick connects in each water nozzle

- Service contract available

Factory-Installed Options

- Enhanced tubing, .028 or .035 in. (0.711 or 0.889 mm):

- Internally/externally enhanced copper tubing - cooler/condenser

- Internally/externally enhanced cupronickel tubing - condenser

- Smooth bore/externally enhanced copper tubing - cooler/condenser

- Smooth bore/externally enhanced cupronickel tubing - condenser - Wall tubes, titanium, condenser, .025 or .028 in. (0.635 or 0.711 mm):

- Internally enhanced tubes

- Smooth bore tubes - Marine waterboxes (available for heat exchanger frames 3-5 only):

- 150 psig (1034 kPa) waterbox

- 300 psig (2068 kPa) waterbox - Nozzle-in-head waterbox, 300 psig (2068 kPa)

- Hinged waterboxes

- Flanged cooler and/or condenser waterbox nozzles

- One, 2, or 3 pass cooler or condenser waterside construction

- Zinc anodes

- 100K AIC high interrupt circuit breaker with shunt trip

- Analog voltmeter and ammeter with 3-phase selector switch

- DataLINK™ or DataPort™ communication device

- Shipped factory charged with refrigerant

- Hot gas bypass

- Full cold surface thermal insulation (except waterbox covers)

- Customer factory performance testing

- Export crating

Field-Installed Accessories

- BACnet™ Carrier translator

- DataLINK™ or DataPort™ communication device

- LonWorks® Carrier translator

- Sensor package

- Separate storage tank and pumpout unit

- Stand-alone pumpout unit

- Soleplate package

- Spring isolator kit

- Refrigerant isolation valves for in-chiller refrigerant storage

- Unit-mounted pumpout unit for storing refrigerant inside the chiller during servicing

- Acoustical sound insulation kit

- Shipped fully charged

| Nominal Capacity (Tons)* | Heat Exchanger Size | Length with Nozzle-in-Head Waterbox | Width | Height | |||||

|---|---|---|---|---|---|---|---|---|---|

| 2-Pass** | 1 or 3-Pass | ||||||||

| ft-in | mm | ft-in | mm | ft-in | mm | ft-in | mm | ||

| 250-550 | 30 to 32 | 13-8¼ | 4172 | 14-3¼ | 4350 | See Unit

Certified Drawings |

See Unit

Certified Drawings |

||

| 35 to 37 | 15-4¾ | 4693 | 15-11¾ | 4870 | |||||

| 40 to 42, 4D

|

14-3 1⁄8 | 4347 | 14-9 | 4496 | |||||

| 45 to 47, 4E

|

15-11 5⁄8 | 4867 | 16-5½ | 5017 | |||||

| 50 to 52 | 14-4½ | 4382 | 14-10 | 4521 | |||||

| 55 to 57 | 16-1 | 4902 | 16-6½ | 5042 | |||||

*For job specific dimensions and weight information, please contact your Carrier Sales Representative.

**Assumes all customer connections are on the same end of the chiller.

- Catalog Carrier 23XRV Published Date: 30/05/2023

- 23XRV Guide Specifications, 175 to 550 Tons (615 to 1934 kW) Nominal_Published Date 3.1.2018 Published Date: 01/03/2018

- 23XRV AquaEdge® High-Efficiency Variable Speed Screw Chiller with with Greenspeed® Intelligence, 50-60 Hz, HFC-134a Published Date: 14/08/2020

- Carrier® ChillerVu™ 23XRV Series Counterflow Application Guide Published Date: 05/04/2021

- Carrier® ChillerVu™ Variable Flow Condenser Pump Application Guide Published Date: 21/12/2020

- EverVu™ Touch Screen Display for Evergreen® 19XR,XRV, 23XRV Chillers with PIC II or PIC III Controls Published Date: 11/07/2015

- Carrier Evergreen 23XRV Water-Cooled Chiller Provides Full-Load and Off-Peak Energy Savings_Published Date 7.10.2015 Published Date: 10/07/2015

- Carrier Introduces New Evergreen Variable Speed Water-Cooled Screw Chiller Published Date: 10/07/2015

- Carrier Moves the Frontier on Efficiency Published Date: 10/07/2015

- Press Release - Carrier AdvanTE3C Optimized Central Plant Solution Reduces Cooling Energy Consumption up to 50 Percent Published Date: 10/07/2015

- Press Release - Carrier AquaEdge® 19XR, 23XR and AquaForce® 30XV and XA Chillers are Available With Lower Global Warming Refrigerant Solutions Published Date: 09/02/2018

- Press Release - Carrier Leads the Industry with the Most Complete Line of Seismic-Compliant Chillers Published Date: 10/07/2015

- Press Release - Carrier Offers Capacity RECOVERY Protection for Mission Critical Market_Published Date 7.10.2015 Published Date: 10/07/2015

- Press Release - Carrier Releases Updated Chiller Mobile App Published Date: 08/08/2019

- Press Release - Carrier Stocks Commercial Applied Products for Rapid Delivery Published Date: 10/07/2015

- Press Release - Carrier to Display Wide Range of Intelligent, Sustainable Building Solutions at AHR Expo Published Date: 16/07/2015

- Press Release - Carrier® Evergreen® 23XRV with Foxfire® Compression Technology Surpasses Industry Efficiency Standard by Up to 44 Percent Published Date: 10/07/2015

- Press Release - Carrier® Expands AquaEdge™ 23XRV Line Published Date: 10/07/2015

- Press Release - Carrier® SMART Service Delivers Enhanced Chiller Performance Published Date: 14/02/2017

- Press Release - Seismic Compliant WeatherMaker (PDF) Published Date: 10/07/2015

- Press Release - U.S. Government Study Finds Variable-Speed Screw Chiller Technology More Efficient Published Date: 15/02/2018

- Press Release -Carrier® to Display Extensive Range of Commercial Products at 2014 AHR Expo in New York Published Date: 10/07/2015

- California Hotel & Casino Published Date: 10/07/2015

- Cashman Center Finds Comfort and Savings with Evergreen® 23XRV Chillers Published Date: 10/07/2015

- Center for Intelligent Buildings Published Date: 10/07/2020

- Crowne Plaza Published Date: 10/07/2015

- Gaston County Medical Building Published Date: 10/07/2015

- Iron Mountain Published Date: 25/10/2018

- LCO Building Published Date: 10/07/2015

- Lehigh Valley Health Network Published Date: 30/11/2016

- Mangabeira Shopping, Brazil Published Date: 07/08/2017

- Mater Hospital, Queensland Published Date: 10/07/2015

- Nemours Children's Clinic Published Date: 10/07/2015

- Shore Medical Center Published Date: 10/07/2015

- University of Maryland Shock Trauma Tower Published Date: 15/05/2017

- Washington Navy Yard Published Date: 16/07/2015

- Waterville TG Published Date: 10/07/2015

- 23XRV AquaEdge® High-Efficiency Variable Speed Screw Chiller with Greenspeed® Intelligence, 50-60 Hz, HFC-134a, 175 to 550 Nominal Tons (615 to 1934 Nominal kW) Published Date: 06/02/2020

- Carrier® ChillerVu™ Chilled Water System Optimizer Product Data Sheet Published Date: 24/03/2021

- Carrier® ChillerVu™ PSM-IO Product Data Sheet Published Date: 17/12/2020

- i-Vu Open UPC Open Factory Installed Product Data Sheet Published Date: 17/12/2020

- Better Than Oil-Free, Why Screw Chillers with Pure Speed Capacity Control Save More Energy Than Magnetic Bearing Chillers Published Date: 16/07/2015

- Chilled Water System Optimizer Published Date: 11/04/2019

- Mechanical Room Update, Considerations In The Application Of Centrifugal Chillers Using Open Drive Motors Published Date: 10/07/2015

- Variable Frequency Drive, Operation and Application of Variable Frequency Drive (VFD) Technology Published Date: 30/07/2018

- Variable Speed Screw Compressor, Raising the Bar for Variable Speed Performance Published Date: 10/07/2015

- 19XRV, 23XRV Chillers with PIC III-PIC 6 Controls, Eaton LCX9000 VFD Option Published Date: 26/08/2019

- 19XRV,23XRV Hermetic Centrifugal Liquid Chillers with PIC III-PIC 6 Controls, Rockwell PowerFlex 755 VFD Option Published Date: 28/08/2019

to find out more, you can contact us at

Inquiry Form Call Center: (+62) 21 2660 8088 Chat with us on Whatsapp